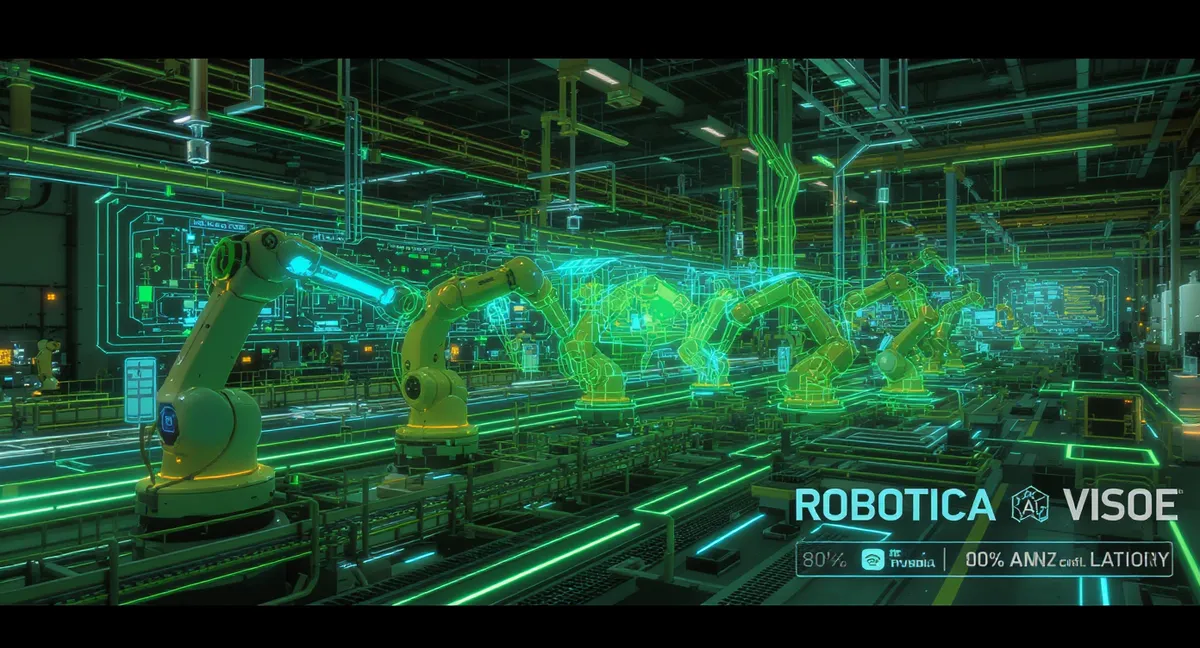

At CES 2026, Caterpillar unveiled a new generation of intelligent, autonomous construction machines—the culmination of more than three decades of automation research. Autonomous excavators, bulldozers, and trucks are moving from experimental technology to production equipment, promising to transform construction sites worldwide.

The Evolution of Construction Automation

Caterpillar has been developing autonomous equipment since the early 1990s. Mining operations were early adopters, with autonomous haul trucks operating in controlled environments for years. Now that technology is mature enough for the less predictable world of construction sites.

The new systems represent a fundamental shift: rather than adding autonomy as an afterthought, these machines embed autonomous capabilities directly into construction workflows.

What’s New

Autonomous Excavators

The new excavators can dig, trench, and grade according to digital site plans without human operators. GPS precision combined with AI decision-making enables accuracy that matches or exceeds skilled operators.

Self-Driving Bulldozers

Autonomous dozers can grade terrain, push material, and prepare sites according to specifications. They work continuously, unaffected by shift changes or operator fatigue.

Intelligent Haul Trucks

Building on mining experience, construction-focused haul trucks navigate job sites autonomously, moving material between locations without human drivers.

Coordinated Operations

Perhaps most impressive, these machines can work together. An autonomous excavator loads an autonomous truck while a dozer prepares the next work area—all coordinated through a central AI system.

The Benefits

Safety

Construction remains one of the most dangerous industries. Removing operators from heavy equipment eliminates risks from rollovers, struck-by incidents, and repetitive motion injuries.

Precision

Digital control enables precision difficult to achieve manually. Grades match specifications exactly. Trenches hit designed depths consistently. Waste from over-excavation drops dramatically.

Efficiency

Autonomous equipment can operate around the clock. No breaks, no shift changes, no overtime pay. For projects with tight deadlines, continuous operation can compress timelines significantly.

Labor Shortage Solution

Construction faces a persistent labor shortage, particularly for skilled equipment operators. Autonomous machines can fill gaps that companies struggle to staff with human workers.

How It Works

The autonomous systems combine multiple technologies:

Positioning

RTK GPS provides centimeter-level positioning accuracy. The machines know exactly where they are relative to digital site plans.

Perception

Lidar, cameras, and radar create a 360-degree awareness of the environment. The systems detect obstacles, people, and other equipment in real-time.

Planning

AI systems convert site plans into sequences of machine movements. They optimize for efficiency while respecting safety constraints.

Control

Advanced actuators and control systems execute planned movements with precision, adjusting in real-time based on sensor feedback.

Current Limitations

Despite the advances, autonomous construction equipment has limitations:

Site Preparation

Fully autonomous operation works best on prepared sites with good GPS reception and clear boundaries. Complex urban environments present challenges.

Task Scope

Current systems excel at bulk earthwork—moving dirt, grading surfaces, digging trenches. Finer work still requires human involvement.

Weather Dependence

Heavy rain, snow, or dust can interfere with sensors. Human operators handle adverse conditions that challenge autonomous systems.

Cost

Autonomous equipment costs more than conventional machines. The economics work for large projects but may not pencil out for smaller jobs.

The Transition Period

Caterpillar isn’t expecting immediate full autonomy. The near-term model involves mixed fleets:

- Autonomous machines handle routine, high-volume tasks

- Human operators tackle complex or unusual work

- Remote operators supervise and intervene when needed

Over time, the balance shifts toward greater autonomy as the technology proves itself.

Industry Impact

If autonomous construction equipment delivers on its promise, the industry impact could be substantial:

- Project costs drop as labor expenses decrease

- Timelines compress with 24/7 operation

- Safety incidents decline dramatically

- Quality improves with precise execution

Looking Forward

Caterpillar’s CES announcement signals that autonomous construction is moving from experiment to implementation. The technology exists. The equipment is ready. The question now is how quickly the industry adopts it.

The job site of the future is taking shape, and it runs on AI.

Recommended Reading

TinyML: Machine Learning on Microcontrollers

Learn how AI runs on embedded systems powering autonomous vehicles and equipment. From sensors to decision-making at the edge.

As an Amazon Associate, I earn from qualifying purchases.

How do you think autonomous equipment will change construction? Share your thoughts in the comments below.

Comments